Transforming Used Oil Analysis with AI-Powered Tribology

Summary

Used Oil Analysis Laboratories perform tests on machine fluids to predict machine failure and preventative maintenance events. One of the key disciplines for used oil analysis is called Tribology. In this article we propose a technical solution driven by Artificial Intelligence to help automate and assist in the Tribologist functions of the lab. LabLynx proposes the use of our LabLynx Lab Automation Suite—a cloud-hosted, LIMS-agnostic platform designed to integrate seamlessly with any laboratory data system.

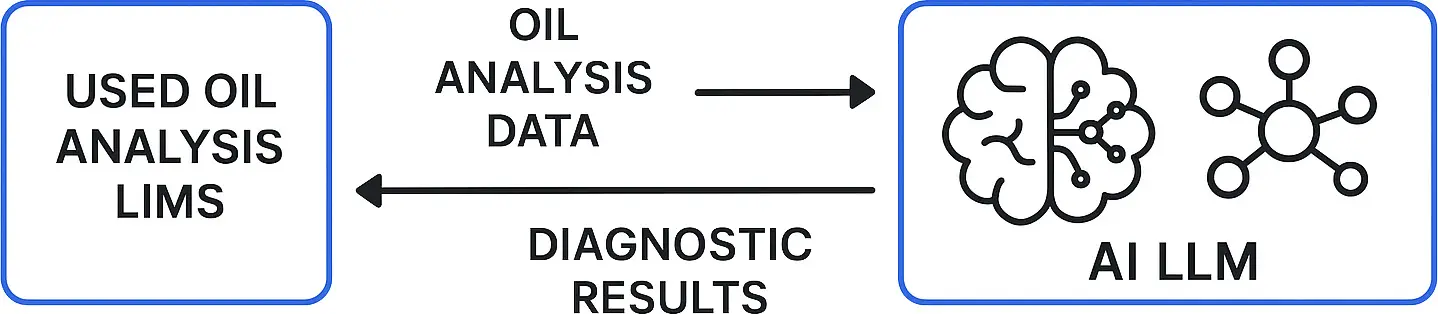

The goal is to extract used oil analysis data from nearly any Used Oil Lab LIMS—data that has not yet undergone tribologist interpretation—and process it through a the LabVia.ai Large Language Model (LLM) / Retrieval-Augmented Generation (RAG) Framework. This private LLM will be specifically trained around the lab's used oil analysis data, using structured tribology rules and proprietary knowledge, including the lab's client-specific information. To enhance its capabilities, the private LLM will be supplemented with a public LLM to generate a comprehensive, AI-assisted tribology analysis.

The core of this solution lies in LabVia, LabLynx’s integration middleware, and the LabVia.ai platform, which powers both the private and public LLM integrations.

LabVia will also provide the UI/UX interface for real-time interaction by human tribologists. Through this interface, users can view a list of samples requiring analysis. These samples will be sent via LabVia to LabVia.ai, where the combined LLMs will perform the initial interpretation. The AI-generated results are then returned to the tribologist, who can review, refine, and annotate the output. These refinements are fed back into the system, allowing the LLM to learn and improve over time based on expert input.

Once the tribologist approves the final interpretations, LabVia will transmit the completed results back to the LIMS for further processing, reporting, and client delivery. The solution can also be run in a pure automated mode or a mixture of both human and AI interactions.

For AI assisted Tribology, much like self driving cars... no sane person wants to be in one without a real driver to take over. Until you can be 100% sure about the results that AI puts out, you should use the human Tribologist to review the AI results and to add value to those AI results so that your LLM becomes more reliable and reflective of your labs quality standards. Basically, AI is a productivity tool and is not a replacement for human ingenuity, creativeness and the collective experience of your Used Oil Analysis Lab.

Components of the LabLynx AI Tribology Solution

Used Oil Analysis LIMS

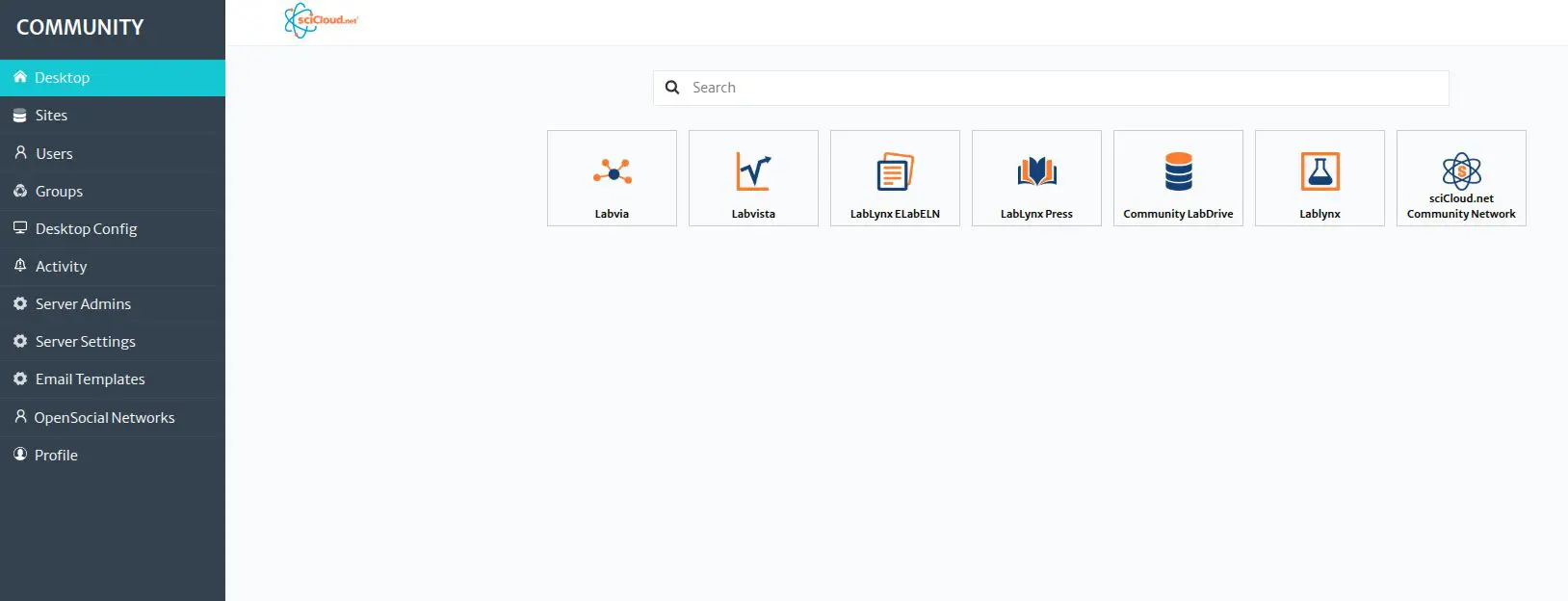

sciCloud.net

Cloud Application Hosting & Cyber Security Platform

sciCloud.net, developed by LabLynx, is a specialized Cloud Application Platform designed to deliver tailored informatics solutions for laboratories. It provides the foundational technology, security, and functionality necessary to support a wide variety of lab environments, ensuring that each implementation meets the specific needs of the individual laboratory.

Through sciCloud.net, laboratories gain access to a robust infrastructure that allows for customization across all critical functional areas, enabling efficient, compliant, and secure operations.

A key feature of sciCloud.net is its integration with LabLynx’s OpenSocial platform, offering Single Sign-On (SSO) and Identity and Access Management (IAM) capabilities. This ensures streamlined user authentication and administration across the platform, enhancing both user convenience and security. Furthermore, sciCloud.net is built with a comprehensive security and regulatory compliance framework, incorporating features that labs depend on to meet industry standards and government regulations.

By providing a secure, scalable, and highly configurable environment, sciCloud.net empowers laboratories to focus on their scientific and operational goals while maintaining confidence in the underlying systems' integrity and compliance. Whether a lab specializes in clinical, environmental, research, or other types of laboratory work, sciCloud.net adapts to support the specific workflows and data management needs unique to each setting. Overall, sciCloud.net represents a flexible, secure, and future-ready solution for modern laboratories seeking to enhance their digital infrastructure and regulatory posture.

sciCloud.net is the hosting and security infrastructure for both LabVia and LabDrive, which are the key components of this AI solution.

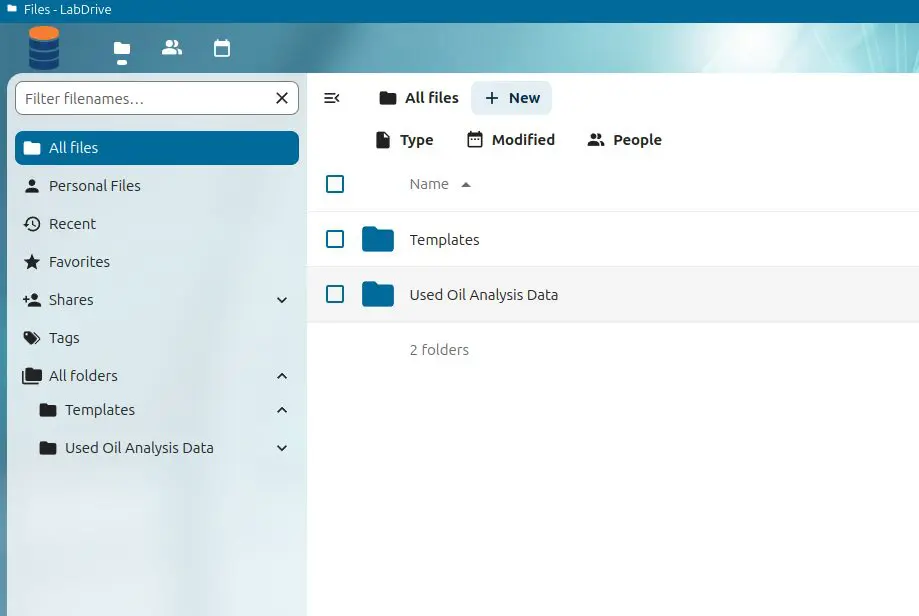

LabDrive

To hold all existing oil analysis data for driving the LabVia.ai LLM/RAG model

Optimized for the complex and sensitive nature of scientific and laboratory information, LabDrive enables labs to securely centralize structured and unstructured data—ranging from research documentation, test results, SOPs, and regulatory records to instrument outputs and domain-specific knowledge bases. With enterprise-grade encryption, access controls, and compliance-focused architecture, LabDrive ensures data integrity and confidentiality, critical for maintaining intellectual property and regulatory adherence.

As laboratories increasingly adopt AI to enhance operational efficiency, automate data analysis, and accelerate scientific discovery, LabDrive seamlessly integrates with AI pipelines. It acts as a secure data lake from which relevant content can be dynamically retrieved, contextualized, and presented by LLMs within RAG frameworks. This empowers AI systems to deliver more accurate, contextual, and compliant outputs by grounding responses in authoritative, lab-specific knowledge.

LabDrive is more than just storage—it is a strategic asset enabling intelligent, data-driven lab environments. Designed for interoperability with LabLynx ELab LIMS and other informatics tools, it supports a future-ready infrastructure where data security, accessibility, and AI-readiness converge.

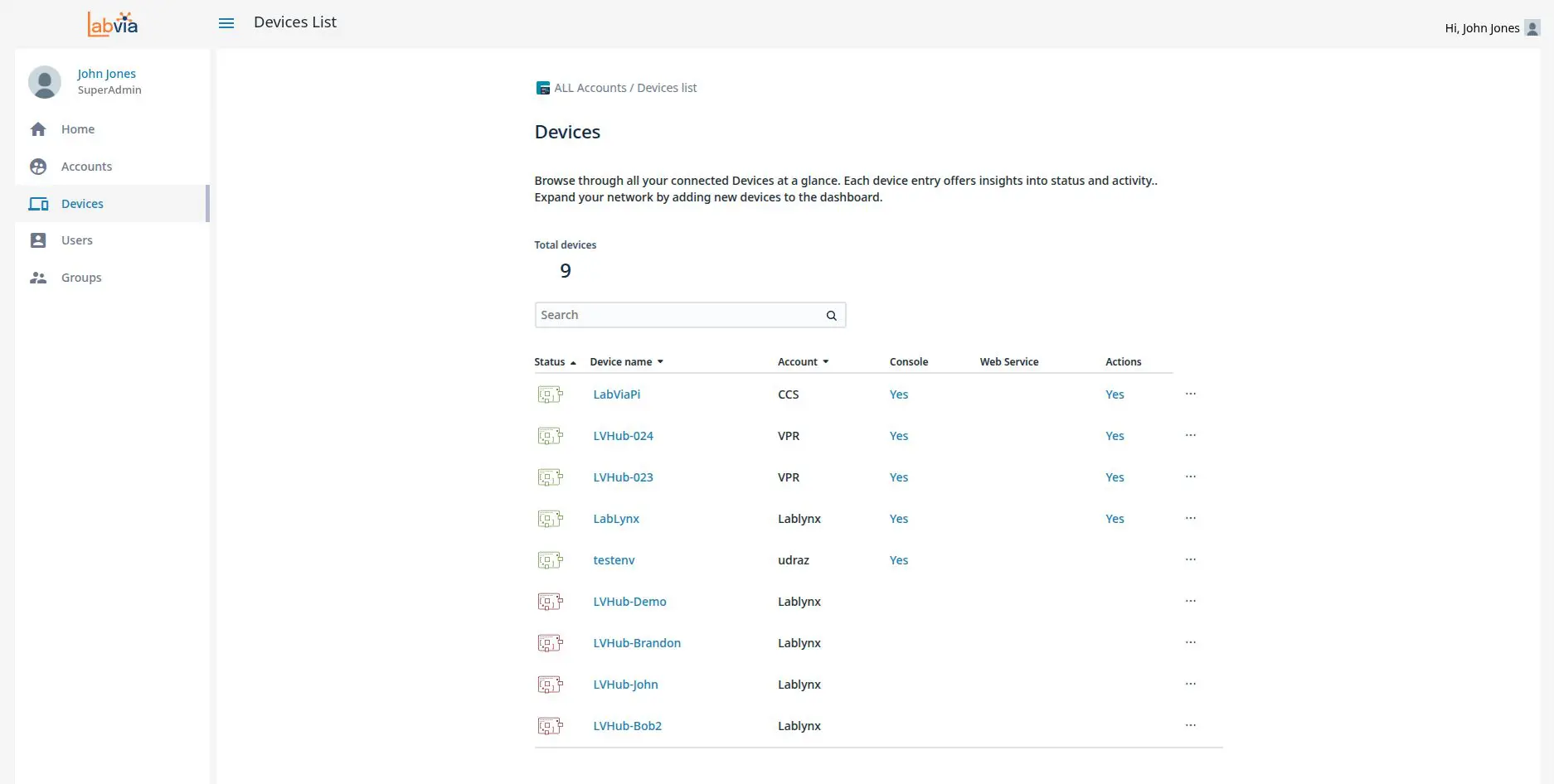

LabVia

To Integrate the Used Oil LIMS with LabVia.ai LLM

LabVia is a powerful, cloud-based integration platform designed specifically for the unique needs of laboratory environments. It enables seamless communication and data flow between a wide variety of laboratory systems, including instruments, Laboratory Information Management Systems (LIMS), Electronic Lab Notebooks (ELNs), data lakes, and other digital infrastructure. By serving as a centralized integration hub, LabVia streamlines laboratory workflows, eliminates data silos, and enhances operational efficiency across research, clinical, and quality control labs.

LabVia offers a low-code, event-driven development environment that allows users to easily design, deploy, and manage data workflows and system integrations through an intuitive, visual interface. LabVia is tailored specifically for laboratory use cases. It supports protocols and data standards commonly used in scientific environments (such as ASTM, HL7, and various instrument-specific formats), enabling faster implementation and higher compatibility with lab systems.

LabVia empowers scientists, IT teams, and lab managers to rapidly build and iterate integration flows without extensive programming knowledge. Its cloud-native architecture ensures scalability, security, and remote accessibility, making it ideal for modern, distributed lab operations. Additionally, its automation capabilities reduce manual data handling, lower the risk of human error, and ensure data integrity across systems.

In essence, LabVia brings the power of modern integration and automation tools to the lab, helping organizations accelerate research, maintain compliance, and improve overall lab productivity.

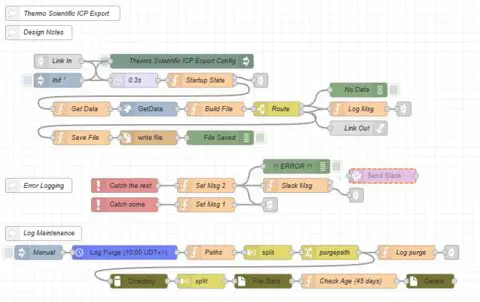

LabVia Studio

To develop and maintain the integrations and UI/UX application

LabVia Studio is a powerful, integrated development environment (IDE) designed to simplify and accelerate the creation of complex integrations across laboratory environments and enterprise ecosystems. Built with a node-based, low/no-code architecture, LabVia Studio empowers users—regardless of technical expertise—to design, deploy, and manage sophisticated workflows that connect lab instruments, enterprise software, cloud APIs, AI platforms, and other digital services.

By leveraging a visual programming interface, LabVia Studio eliminates the need for extensive manual coding, enabling rapid prototyping and deployment. Users can drag and drop functional nodes to create data pipelines, automate repetitive tasks, and orchestrate real-time communication between disparate systems. This intuitive environment bridges the gap between laboratory operations and digital transformation initiatives, providing flexibility for both IT professionals and domain experts.

LabVia Studio supports integration with a broad range of devices and services, including lab instruments, LIMS, ERP systems, RESTful APIs, web services, databases, machine learning models, and cloud-native platforms. Its extensible architecture ensures that new integrations can be added quickly, while built-in tools for debugging, version control, and real-time monitoring enhance reliability and transparency.

Whether you're building a simple automation or an enterprise-grade integration solution, LabVia Studio accelerates innovation by providing a unified platform to connect, control, and optimize digital and physical assets. Ideal for smart labs, digital R&D environments, and data-driven enterprises, LabVia Studio redefines what’s possible in lab integration and automation.

LabVia Studio also provides access to all LabVia Hub IoT devices for integration to systems and devices that are within a secure laboratory network. The LabVia Hub is a small IoT device for integration to lab robotics, instruments and other internal systems.

LabVia UI/UX Custom Application

The tribologist UI/UX to review and submit AI assisted tribology interpretations

LabVia, empowers users to design and deploy custom user interfaces (UI) and user experiences (UX) directly within their flow-based applications. In LabVia Studio, a platform tailored for laboratory automation and data integration, LabVia plays a crucial role in enabling tribologists—experts in used oil analysis—to visualize and interact with complex data in intuitive ways.

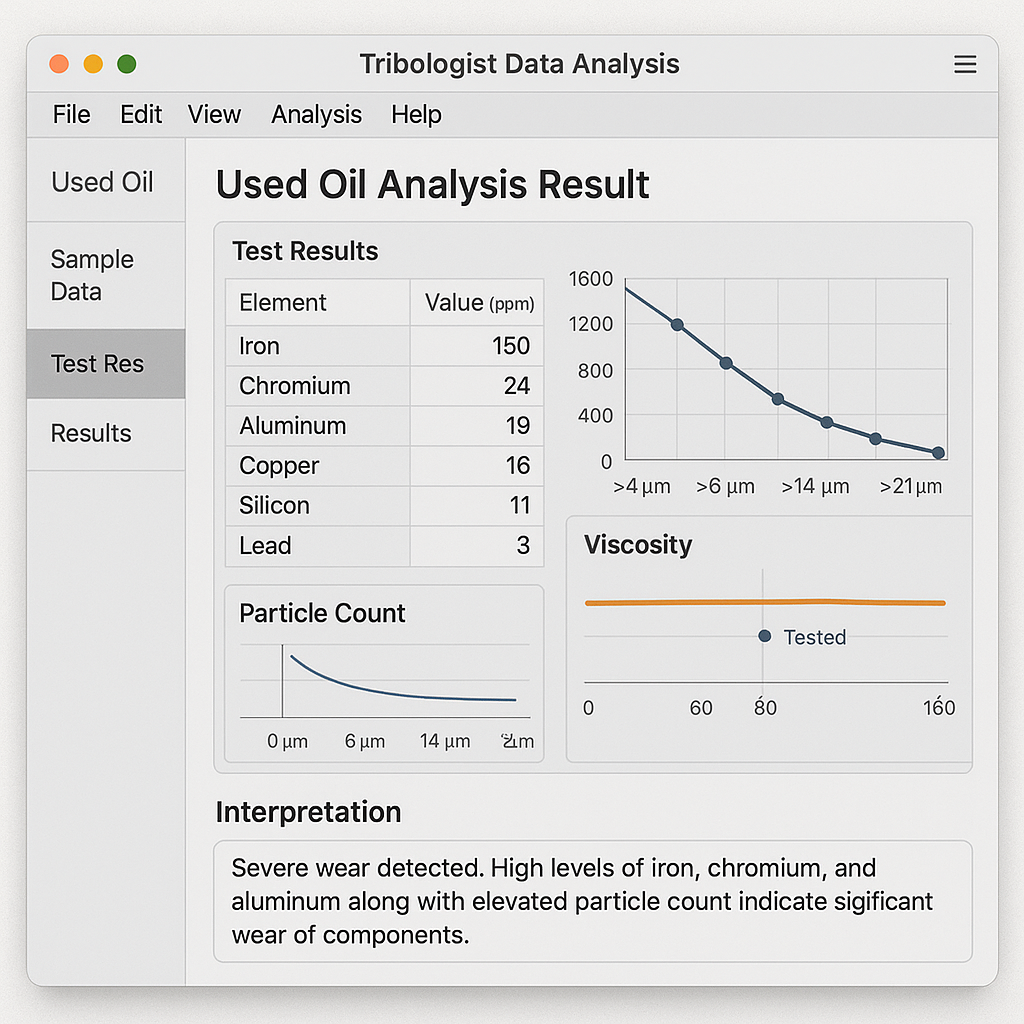

For a tribologist, data such as elemental concentrations, viscosity, wear metal trends, and contamination levels must be monitored and interpreted efficiently. LabVia allows users to have dynamic dashboards that can be tailored to display real-time or historical data specific to their workflows. For instance, a tribologist can have a panel that visualizes trends in iron, lead, or copper over time, indicating engine wear, and correlate these values with viscosity changes or contamination alerts.

LabVia.ai

Integrated Large Language Model (LLM) with Retrieval Augmented Generation (RAG)

LabVia.ai is an advanced artificial intelligence platform designed to enhance laboratory operations by leveraging a private large language model (LLM) integrated with a Retrieval-Augmented Generation (RAG) framework. This architecture enables LabVia.ai to access and utilize proprietary, laboratory-specific knowledge bases, ensuring that the AI's outputs are deeply rooted in the unique data and protocols of each laboratory environment.

The RAG framework allows LabVia.ai to retrieve relevant information from internal databases and combine it with insights generated by public LLMs. This hybrid approach ensures that the AI can provide comprehensive and contextually accurate responses, enhancing decision-making processes within the laboratory setting.

By integrating both proprietary and public data sources, LabVia.ai offers a dynamic tool for laboratories to streamline workflows, improve data analysis, and support research initiatives. The platform's ability to adapt to specific laboratory needs while incorporating broader scientific knowledge makes it a valuable asset for modern laboratories aiming to enhance efficiency and innovation.

In summary, LabVia.ai represents a significant advancement in laboratory AI applications, combining the strengths of private LLMs and RAG frameworks to deliver tailored, intelligent solutions that bridge the gap between proprietary laboratory data and the expansive knowledge of public LLMs.

System & Data Security Considerations

Cloud Hosting Security

At LabLynx, our security plan is currently based on NIST 800-53 v4. Security and privacy controls are maintained such that our clients are capable of complying with their many security, privacy, and laboratory standards, frameworks and regulations.

LabLynx hosts at Amazon Web Services (AWS) where all physical infrastructure and physical security are second to none. You can view the AWS SOC 3 report here. LabLynx uses the AWS network for User Authentication, Network Security, VPS IaaS, PaaS, and all customer data is isolated with limited access. Development boxes are maintained at AWS. The global information system infrastructure resources and services provided by AWS are located in the US and other AWS countries where applicable. AWS offers FedRAMP compliant services (AWS US East-West).

LabLynx conducts regular security assessments, security audits, and internal risk assessments of the information systems. The company also finds potential risks posed to the information system from external parties (e.g., service providers, contractors operating information systems on behalf of the organization, individuals accessing organizational information systems, and outsourcing entities). LabLynx conducts regular vulnerability assessments of the information systems. LabLynx employs vulnerability scanning tools that allow the list of vulnerabilities tested to be automatically updated.

Disaster Prevention & Recovery

We take regular backups of all production environments with AWS, which are synchronized to multiple data centers in the AWS region. Backups are kept for 10 weeks. Backups are encrypted. All environments are scanned for malware, viruses, and other malicious code.

Each part of the DRP is tested annually for effective operation and successful information system operation at the selected disaster recovery site. Alternate recovery sites are maintained in case of major disaster. Clients can request disaster recovery testing in the Project Plan as a Planning Milestone in compliance with a contract between the customer and LabLynx Inc.

The hosted network is physically and logically isolated from all remote locations, including the company offices. It is hosted with AWS, for which personnel, guests, or otherwise, have no physical access. Damage to central offices or any other remote site will not impede continued work from other locations.

An estimated RTO time frame is based on one (1) hour per 100GB of restored data plus one (1) hour system configuration.

- Server Instance Disaster: A server instance disaster would require restoring the destroyed server into a new instance at AWS from the most recent backup.

- VPC/Network Disaster: A VPC/Network disaster would require restoring the destroyed VPC from the CloudFormation template backup.

- AWS Availability Zone Disaster: A disaster event for an AWS availability zone would require restoring the destroyed environment into the alternate, functional AWS region.

Laboratory Intellectual Property Protection

What parts of the solution are owned by the lab and which are not?

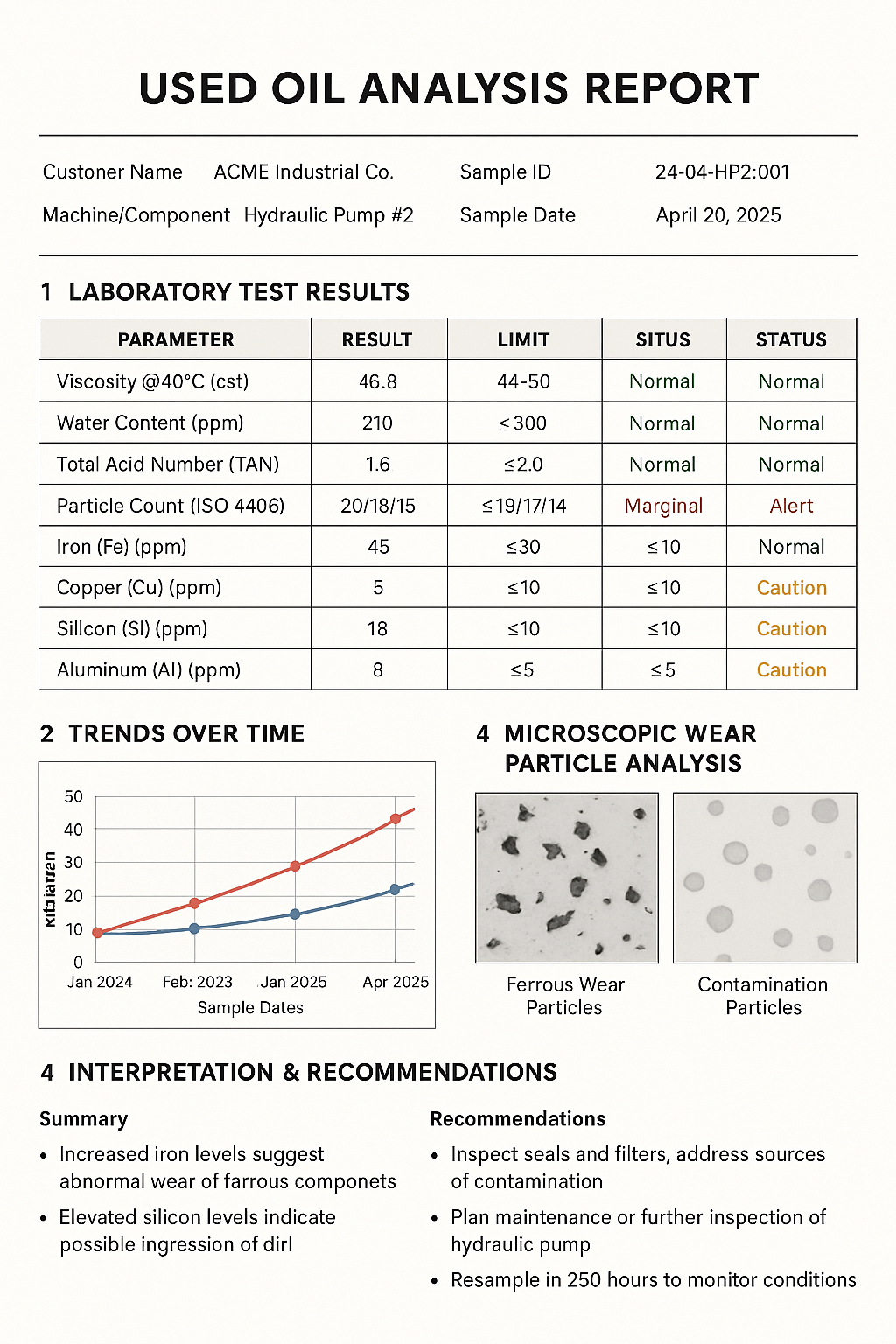

A Demonstrated Proof of Concept and the Results

The following transcript is where we provided example used oil analysis data to the AI LLM and had it read the data for the two samples on a piece of equipment and provide an AI Tribologist interpretation of that data. We compare its analysis and interpretation to that of a human tribologist where the human interpretation is thin and lacks significant value compared to the AI interpretation.

Test the AI Tribology Solution for yourself with your data and you determine if it will provide the results your lab and clients need.

Data to be Analyzed

| Equipment ID | LabLynx T1-2-3, Case 23 T1-2-3 | LabLynx T1-2-3, Case 23 T1-2-3 |

|---|---|---|

| Date | 9/19/2024 | 7/28/2024 |

| Hours On Oil | 59 | 51 |

| Oil Type | Arctic Cat 0W40 ACX | Arctic Cat 0W40 ACX |

| Viscosity @ 100°C | 10.7 | 10.41 |

| Fe (Iron) | 10 | 13 |

| Cu (Copper) | 4 | 3 |

| Pb (Lead) | 3 | 1 |

| Si (Silicon) | 14 | 21 |

| Al (Aluminum) | 6 | 8 |

| Fuel % | 5.2 | 1.6 |

| TBN | 6.04 | 8.44 |

| Oxidation | 12 | 34 |

Laboratory Intellectual Property Protection

| Equipment ID | LabLynx T1-2-3, Case 23 T1-2-3 | LabLynx T1-2-3, Case 23 T1-2-3 |

|---|---|---|

| Date | 9/19/2024 | 7/28/2024 |

| Hours On Oil | 59 | 51 |

| Interpretation | OK: This fluid meets all the criteria of the new or typical trends of the equipment. | Attention: Certain criteria of the sample are at or approaching limits. Action should be taken soon to prevent damage. Silicon is above warning limit. Common sources are dirt contamination, seals, or piston coatings. |

The AI Tribologist Interpretation

| Equipment ID | LabLynx T1-2-3, Case 23 T1-2-3 | LabLynx T1-2-3, Case 23 T1-2-3 |

|---|---|---|

| Date | 9/19/2024 | 7/28/2024 |

| Interpretation |

✅ Iron (Fe), Copper (Cu), Lead (Pb), Silicon (Si), Aluminum (Al): All within acceptable wear levels. ⚠️ Fuel Dilution (5.2%): Significantly above the normal threshold (2.0% max). This suggests: • Possible fuel injector leakage or incomplete combustion. • May lead to viscosity loss, reduced lubrication, and accelerated wear. ✅ TBN (6.04): Still within acceptable range (additive package is healthy). ✅ Oxidation (12): Low — no significant oil degradation. |

⚠️ Silicon (Si) = 21 ppm: Slightly over the contamination threshold (20 ppm). Indicates: • Possible dirt/dust ingress from air intake system or seal issues. ⚠️ Oxidation = 34: Exceeds the recommended limit (30), suggesting oil is beginning to degrade, likely due to heat or extended service interval. ✅ Fuel Dilution = 1.6%: Within acceptable range. ✅ TBN = 8.44: Excellent additive reserve remaining. |

| Diagnosis | High fuel dilution is the main concern. A mechanical inspection of the fuel system is recommended. If not resolved, fuel dilution can significantly reduce oil performance and increase engine wear. | The increased levels of silicon and oxidation suggest external contamination and thermal breakdown. It is advisable to check air filters and seals, and consider shortening the oil drain interval. |

|

Recommendations

A sharp increase in oxidation between oil samples, especially in a relatively short operating window (in this case, from 12 to 34 in just 8 more hours on oil), can be a red flag. Here are the most likely causes: Primary Causes of Sharp Oxidation Increase Elevated Operating Temperatures

Fuel Dilution (Previous Sample Influence)

Extended Oil Use or Delayed Oil Change

Air Ingress or Contamination

Oil Incompatibility or Mixing

The Chemistry Behind It Oxidation in oil is a chemical reaction between the base oil and oxygen, typically accelerated by:

As oxidation increases:

Suggested Next Steps

| ||

Demonstrate the LabLynx AI Assisted Tribologist with your Data

Want to test it yourself? You can. Upload up to 5 sample records to our live demo and let the AI provide a full diagnostic report you can compare to your existing outputs.

Be sure to compare the diagnostics results from AI as compared to the diagnosis on your existing reports for the data you tested with. You will start to experience and imagine what all you can do to provide added value to the analysis service provided to your lab clients.

Conclusion

Using AI for Used Oil Analysis Interpretation: Unlocking New Opportunities

While artificial intelligence is relatively new in the business and professional world compared to the long-standing tradition of used oil labs performing conventional tribology, it offers a transformative opportunity. AI can significantly enhance the productivity, consistency, and scalability of any used oil lab's tribology department without requiring major changes to existing systems.

By integrating AI into the interpretation process, labs can:

- Increase Productivity: AI accelerates data analysis and decision-making, freeing up human tribologists to focus on higher-level tasks.

- Enhance Consistency: AI provides uniform interpretation of oil analysis data, reducing variability that can occur with human-only assessments.

- Improve Client Value: More insightful and transparent reports add value to client interactions and strengthen trust.

- Address Staffing Challenges: AI helps mitigate issues with hiring and retaining skilled tribologists by optimizing the capabilities of existing staff.

- Boost Profitability: By increasing operational efficiency and reducing the need for additional hires, AI directly contributes to the lab’s bottom line.

- Simplify Training and Onboarding: New tribologists can be trained faster and more effectively using AI-assisted learning, drawing from a rich database of knowledge.

- Scale Operations: AI enables the lab to grow without proportional increases in staffing costs, making it easier to handle larger volumes of work.

Importantly, this solution works alongside the systems already in place, enhancing current operations rather than requiring costly replacements.

Why AI Outperforms Traditional Rule-Based Systems

Traditional rule-based approaches, while once effective, have major limitations:

- Inflexibility: Rules must be manually updated and maintained, which is time-consuming and requires scarce expertise.

- Lack of Learning: Rule-based systems do not adapt or improve naturally over time, unlike AI models that evolve with new data.

- Canned Interpretations: Without constant updates, rule-based interpretations can become generic and less meaningful to clients.

- High Maintenance Costs: Maintaining a rules engine is expensive, and failure to do so results in outdated and low-value analysis.

AI, in contrast, mirrors the nuanced judgment of experienced tribologists, continuously learning and adapting, and delivering interpretations that are both more accurate and more insightful.

In short, AI doesn't just automate interpretation — it elevates the entire used oil analysis process, helping labs deliver better service, operate more efficiently, and grow more sustainably.