In Murfreesboro, Arkansas you can visit Crater Diamonds State Park and with a little digging, you’ll walk out with a diamond1. One visitor walked out with an 8.52-carat gem. In Franklin, New Jersey and nearby Sterling Hill, you can find 350 different mineral species, two dozen of which haven’t been found anywhere else2. The Jade Cove Trail in Big Sur, California is a good place to find jade gemstones on the ground in plain sight.

All these sites represent places you can find a wide variety of minerals, metals, and gems. Once you’ve found something, among the first questions you’ll ask is “what is it?”, and, “how valuable is it?” Answering those questions typically requires laboratories that can perform an analysis of the found materials. Today’s mining and metals labs have moved from depending on simple chemical tests to using sophisticated instrumentation that can give you detailed information about the composition of your find and if it has any value. These modern labs are not free from the challenges of rapidly and accurately making such analyses. They are under continual pressure to provide higher productivity and reduce costs; accomplishing that depends upon automation and laboratory informatics.

This article will look first at what the mining and metals industries are all about and how they operate and then address the role that associated laboratories play, looking specifically at the software systems used to help them carry out their work.

Mining

The methodology for searching for valuable minerals and gems as described above is not too different from that used by people in the Bronze and Iron Ages when they were initially looking for potential ore deposits. However, if you want these and other minerals and gems in commercial quantities you need a different, more productive, approach: mining.

There are four types of mining practices that are used for commercial purposes: surface, underground, placer, and in-situ mining.

Surface mining

Surface mining is another way of saying “digging” on a much larger scale, gradually removing material, exposing new layers of earth, and extracting ore that can be processed and refined into a useful product. The most common forms of surface mining are shown in the bullets below:

- Strip mining is most commonly used for coal and hard The area to be mined is cleared of all rocks and vegetation. The area is then dug out with large machines, and that raw material is transported to a facility for processing.

- A variation of this is mountaintop removal. This is used for example, in the Appalachian Mountains to expose coal seams that are broken apart using explosives, exposing enough surface area to permit material to be removed and processed.

- Open-pit mining methods are used to extract gold, silver, and The technique creates a large hole via digging and explosives with the resulting ore removed with conveyor belts to processing facilities.

Surface mining can result in a variety of problems including environmental impact, erosion, pollution, and the need for site remediation when the mine is closed.

Underground mining

Underground mining is another variation of digging, where you just create a series of holes and tunnels into the earth instead of removing it layer by layer. This is commonly used for iron, coal, oil, and diamonds. Two major benefits of this technique are a reduction of the amount of damage done to the environment, and, reduced exposure to weather conditions. The dominant risks, however, are to human health and safety. We periodically read about mine collapses where miners have to be rescued. Beyond that, the environmental impact and pollution are ongoing concerns.

Placer mining

Placer mining is what we usually picture for the California Gold Rush (1848-1855). Water is used to carry sedimentary rock layers in the form of small particles that are then separated into waste material and the desired product. This mining technology has a lower environmental impact since the land itself is not disturbed; however, water sources are easily contaminated.

In-situ mining

If we inject chemicals into an ore deposit either above ground or underground, we can dissolve the metals we are targeting and pump the resulting material into a processing facility for extraction. That, essentially, is what in-situ mining is all about. It is often used for the mining of gold, silver, zinc, lead, and uranium among other desirable targets.

The primary benefits of in-situ mining are minimal noise, reduced visual disturbance, and the ability to recycle the water used in the process.

Issues and research topics in the mining industry

The mining industry comes with a number of concerning topics, which lead to their own research programs. Those topics include issues related to the environment (e.g., pollution, damage to the environment, and site remediation), health, safety, and exploration of new sources of products. That has led to work in:

- Geophysical sensing techniques;

- Mine health and safety;

- Mineral and chemical characterization;

- Mineral processing, geometallurgy, and extractive metallurgy;

- Mine technology and automation;

- Rock strength, fracturing, and excavation; and,

- Sustainable mining and

In the United States, the industry’s regulatory oversight is provided by the Bureau of Land Management for mining operations on federal lands (BLM, US Department of the Interior), the Environmental Protection Agency (EPA), and the US Occupational Safety and Health Administration (OSHA). The minerals found on federal lands (under the purview of the BLM) are classified into three forms: locatable (e.g., gold, silver, copper, and hard rock minerals), leasable minerals (e.g., coal), and, saleable minerals (e.g., sand and gravel).

Laboratories in the mining industry

There is little in the way of laboratory research in mining aside from method development and materials identification. Most laboratory work is done using the service lab model (described below) with methods developed either in-house or through standards groups like the ASTM3, or those required by the EPA. There are three types of laboratories used to support mining operations: fixed laboratories, mobile laboratories, and, specialized on-site automated laboratory systems.

Fixed laboratories are those that we commonly encounter when thinking about lab operations. They provide facilities for sample preparation, materials characterization, and analysis of physical and chemical properties. Chemical tests include those most commonly used for inorganic materials such as atomic absorption, X-ray fluorescence (XRF), X-ray diffraction, etc. Many of these procedures are also used in metals testing. Materials characterization can include optical and electron microscopy, microanalysis using electron microprobes and laser ablation. Rock hardness testing and evaluation may also be included.

Mobile testing labs are used in remote areas where access is difficult and sending samples to a fixed lab might entail significant delays in obtaining results. These labs use simple test procedures and avoid equipment that is easily damaged, requires frequent recalibration, or requires large amounts of consumables. Devices such as hand-held XRF are ideal for this work as is other testing equipment for material physical properties.

Specialized on-site automated laboratory systems are expensive alternatives to mobile testing labs that offer the more sophisticated analyses necessary in order to meet regulatory requirements. This type of installation does offer some advantages in efficiency, consistency, and security.

Metals

Materials and metals research has been carried out in civilizations for thousands of years4. The civilization with superior materials and metal technologies had a significant military and economic advantage over its neighbors. The application of those materials has moved from sharper swords, tools, and better jewelry to the fabrication of parts for cars, airplanes, spacecraft, and household goods. The end result is still the same: the company or country with the most advanced materials technologies holds economic, political, and military advantages. Technology development has moved from simple alloys to more sophisticated uses.

The goal of the mining industry is to remove ore from the ground so that it can be sold or to refine it into purified ingots so that it can be placed on the market. The metals industry takes the next step by converting those raw mined materials into refined products that can be used to produce components for the consumer marketplace. Research in the metals industry covers a wide range of applications, the following list is just a few of the types of work that are going on:

- Nanotechnology: understand the control of matter on atomic and (supra)molecular scales;

- Room temperature superconductors: strive to reduce energy costs and make magnets used in medical applications less costly to fabricate and use.

- Rare earth magnet alternatives: discover replacements for rare earth magnets for geo-political purposes. (Rare earth materials are used in applications that include lasers, magnets, batteries, and fiber-optic Replacements for them are being sought for geo-political purposes. Most of the rare earth materials, over 91%5, are sourced from countries that are unfriendly to the United States and Western Europe, potentially putting those areas at a disadvantage if China, for example, decided to withhold those materials from the marketplace.)

- Corrosion resistance: reduce replacement costs of metal

- Semiconductors: expand development and efficiency as they are used in almost all electronics. Battery technology, lithium replacement: find alternatives to lithium6. (Lithium is a rare and expensive material, widely in demand for battery technology, and not environmentally Some 2.2 million liters of water is needed to produce one ton of lithium7.)

Even more advanced research into metals remains ongoing. For example, research at Northwestern University8 is looking into:

- Shape-memory alloys for biomedical

- Multicomponent alloys for lightweight vehicles or high-temperature

- Intermetallic alloys for hydrogen storage

Laboratories in the metals industry

Both research and testing labs (see the service laboratory model described below) are used to support work in metals development and evaluation. Research labs can range from traditional lab bench operations to larger facilities and pilot plant operations depending upon the equipment being used, and, the need to scale up materials production from small lab samples to a larger quantity, used to see if production operations can scale up successfully.

Testing labs will consist of both chemical composition and physical properties evaluation. Chemical and physical properties tests to determine materials evaluation may be developed in-house, be provided by a customer, or come from established test development organizations such as the ASTM and the International Organization for Standardization (ISO). In addition to research and supporting service labs, production operations will be supported by quality control operations.

The testing of ores and metals can be broken down into three categories: chemical analysis, mechanical testing (i.e., physical properties), and materials characterization. In addition to those test types noted above for mining, chemical analysis also includes optical emission, (for determining elemental composition), positive materials identification, Fourier-transform infrared spectroscopy analysis (FTIR: used in the identification of minerals and structures), and other types of testing. Examples of mechanical testing include flexural testing, impact resistance, hardness, tensile testing, abrasion testing, etc. And material characterization testing includes particle analysis, scanning electron microscopy, and coating analysis.

Laboratory accreditation in the metals and mining industries

The laboratories in both industries need to be accredited through the ISO 17025 standard and the American Association for Laboratory Accreditation (A2LA)9. ISO 17025 certification10 is designed to demonstrate technical competence for analytical results as well as the lab’s management structure. A2LA is the largest independent accreditation organization in the world and operates as a non-profit organization.

Accreditation for labs in the mining industry is required by both states within the US and international groups. In Nevada, labs, including sub-contractors, must be active in that state’s laboratory certification program. In Chile11, the National Service of Customs specifies that the testing of fine copper is carried out in an accredited laboratory. In Serbia, the Serbian Directorate of Measures and Precious Metals requires the implementation of ISO/IEC12 17025 standards.

Informatics in laboratory work

Research

Research and product development projects will vary widely in complexity. However, regardless of the nature of the research, there are elements that are common to most research projects, including:

- Project description, including the entire program or a subset of the activities;

- Planning;

- Development and experimentation;

- Data and observation analysis;

- Results communication and sharing; and

- Preparation of documentation, reports, patent filings,

Some research work could benefit from laboratory informatics systems. These are data collection, and database systems that act as data aggregators/concentrators taking data and information from instruments and observations, and then organizing to be more easily used thus increasing their value to the organization.

The use of laboratory informatics in research can:

- Improve communications by giving more people easier access to the data they need to make decisions;

- Provide a basis for geospatial data analysis, permitting researchers to extract key data elements and look at them across a broad land surface to find patterns of concentrations of valuable ores;

- Make it easier to detect developing problems in areas like environmental remediation, and;

- Allow for better decision-making about the direction of research

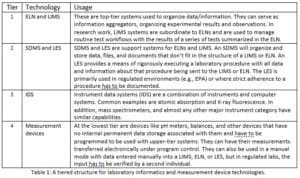

There are four tiers of laboratory informatics that can be used in that process. The informatics systems among those tiers (Table 1) include electronic laboratory notebooks (ELNs), laboratory information management systems (LIMS), scientific data management systems (SDMS), laboratory execution systems (LES), and instrument data systems (IDS).

The most likely tools used in research are those in Tier 1; ELNs are used to record the details of projects and their development, and LIMS is used to record the results of testing which may be part of the research lab or sent to a third-party service lab for test work. (Service labs can also provide a quality control function where needed.) Large projects can benefit from cloud-based systems to share data between geographically dispersed facilities.

Service lab operations

Material testing is an essential part of product development and research, as well as production in the form of quality control. That testing can be extensive, as can be the record-keeping and management of testing programs. Fortunately, such work can be done more easily with the aid of a LIMS.

LIMS has three functions that help support laboratory testing:

- Workflow management – What work is coming in? What has to be done? What are the priorities? What results have to be approved and released? These are routine questions that occur in any production operation and testing labs are a prime example. These and related questions to lab operations are addressed by a LIMS. As part of its operations management samples can be logged in at the lab or remotely (and then identified as “in the lab” when they arrive). This makes it easier to keep track of work that is coming in and plan each day’s testing

- Results management and data logging/capture – LIMS provides a complete database for capturing and organizing samples and test Results can be entered manually, or for more efficiency via electronic data/information transfer from instruments and IDSs. Most major IDSs have programming interfaces that permit downloading of work that has to be done through the IDS, and then upon completion permit sending the sample IDs and results back to the LIMS. This avoids manual data entry, greatly improves productivity, and provides a basis for 24/7 operations.

- Regulatory support – This is an important aspect of a LIMS’ capabilities. It provides traceability for data; if results are challenged, the lab can respond to it by looking at the data history (including audit trails), who carried out the analysis, and who approved the The lab can also see what equipment was used and verify its readiness for use. This becomes important when labs have multiple responsibilities, for example to the EPA.

Because of the different types of laboratories used in the mining industry, a cloud-based LIMS could be of particular benefit. Consider a project that uses both centralized tests in a laboratory with instrumentation supporting remote labs that are close to the mining operations. A cloud-based system could be used to organize testing, and allow a central lab to evaluate results and make recommendations about additional testing to support environmental compliance for example. If there were questions about a set of analytical results, samples could be sent to the central facility for more detailed analysis.

In closing…

Laboratories in the mining and metals industries are under considerable pressure to turn out results as quickly as possible, and keep a close eye on costs. Speed is an issue because waiting for results can delay the progress of mining operations. Costs are an issue particularly in remote lab operations since consumables can be expensive not only due to the cost of the material but also because of the cost of transportation and delays in sample processing if key ingredients for a test are in short supply. In the metals industry, even though the labs are close to the research or production facilities (for example, quality control, which analyzes incoming raw materials as well as products), turnaround time is still a key metric since delays in test results may impact the production process. The same holds true for research programs.

In both environments, laboratory informatics applications, particularly ELNs and LIMS can provide a central repository for test results and make coordination of distributed research and production operations easier. Laboratory managers need to recognize the benefits of informatics early in the development of laboratory operations so that they can gain the most benefit from them. Cloud-based systems can assist the implementation process by providing access to ready-to-run systems that do not require installation or IT support.

Footnotes

1 https://www.smithsonianmag.com/travel/hidden-gems-hunt-treasure-these-geological-sites-180957962/

2 https://www.sterlinghillminingmuseum.org/minerals-of-sterling-hill-and-franklin

3 The ASTM was formerly known as the American Society for Testing Materials until its work took on and international perspective.

4 Sass, Stephen. The Substance of Civilization, New York: Arcade Publishing, 1998

5 https://www.clearias.com/rare-earth-elements-ree/#what-are-the-uses-of-rare-earth-metals-rems-in-defense and https://www.prnewswire.com/news-releases/importance-of-rare-earth-elements-rees-soars-as-demand- increases-301248259.html

6 https://www.autoevolution.com/news/scientists-are-looking-to-replace-lithium-in-batteries-calcium-may-be- the-way-181257.html

7 https://www.euronews.com/green/2022/02/09/we-re-facing-a-lithium-battery-crisis-what-are-the-alternatives

8 https://www.mccormick.northwestern.edu/materials-science/research/areas-of-research/metals.html

9 https://a2la.org/about/

10 https://17025store.com/iso-17025-standards/what-is-iso-17025/

11 https://publicsectorassurance.org/case-study/accreditation-stipulated-for-laboratories-testing-minerals-and- metals/

12 IEC – is the International Electrotechnical Commission, https://www.iec.ch/homepage